LTC Dry™

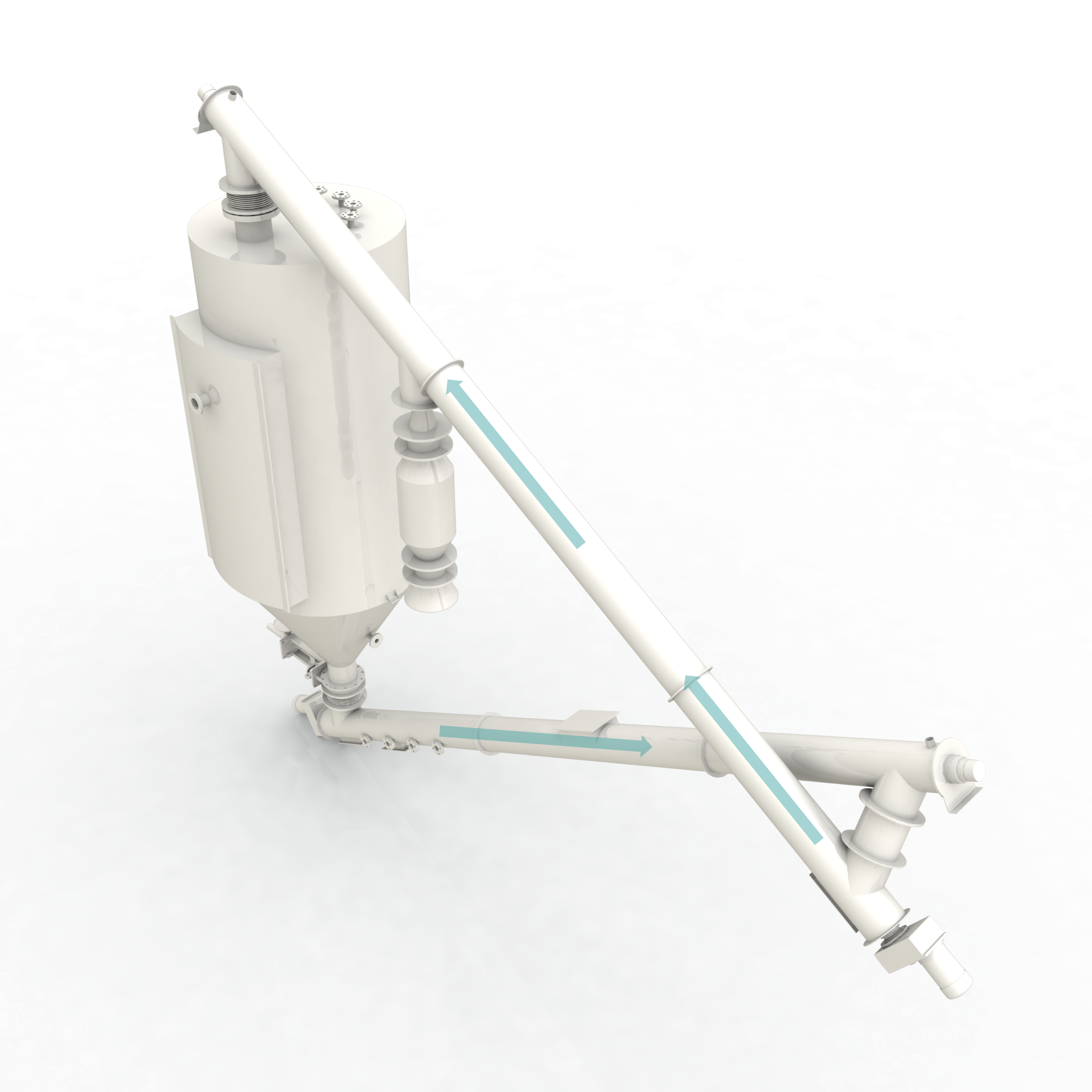

Heartland’s LTC Dry™ solution uses low-temperature conductive drying for sludge conditioning operations.

State of the art sludge drying

LTC Dry™ is designed to address the challenges faced by both municipal and industrial waste generators. Our advanced thermodynamic process utilizes dry matter for economical and reliable heat transfer.

How it works

1. Heating Zone

Thermal energy is added to the dry solids in storage which are fully circulated through the entire system. This is the heat sink for the drying process in the evaporation zone.

1. Heating Zone

Thermal energy is added to the dry solids in storage which are fully circulated through the entire system. This is the heat sink for the drying process in the evaporation zone.

2. Feeding Zone

Wet biosolids are pumped and injected into the dryer loop system at a specified (dry: wet) ratio depending on feedstock.

2. Feeding Zone

Wet biosolids are pumped and injected into the dryer loop system at a specified (dry: wet) ratio depending on feedstock.

3. Drying Zone

Low-temperature conductive (LTC) drying occurs as the screw conveyor mixes wet and dry solids.

3. Drying Zone

Low-temperature conductive (LTC) drying occurs as the screw conveyor mixes wet and dry solids.

4. Recovery Zone

Under high vacuum conditions, water vapor is collected, condensed, and sent for recovery.

4. Recovery Zone

Under high vacuum conditions, water vapor is collected, condensed, and sent for recovery.

5. Product Zone

95% dry solids (DS) are removed from end of the dryer conveyor for subsequent thermal destruction. The remaining dry material is recycled to the bulk heating silo for reuse.

5. Product Zone

95% dry solids (DS) are removed from end of the dryer conveyor for subsequent thermal destruction. The remaining dry material is recycled to the bulk heating silo for reuse.

-

Low Operating TemperaturesLow heat requirement due to dry matter conductive heating operated at low pressure.

-

Enhanced Thermal EfficiencyDesigned to utilize low-temperature waste heat sources from companion thermal destruction systems.

-

Low EmissionsLess odors and volatiles due to lower operating temperature.

The impact of LTC Dry™

Heartland’s LTC Dry™ is a state-of-the-art technology that sets new standards in sludge drying operations.

-

High Thermal EfficiencyUses conductive heat transfer with indirect heating from a variety of low-temperature external sources (ie. fuel sources such as NG, propane, steam, electric heating, and other waste heat sources).

-

Operates with High Levels of Reliability and SafetyProcess uses no external drying air and operates under strong vacuum at low temperatures and requires limited operator attention.

-

Inherently Robust and Resilient ProcessProcess starts with already dry and preheated biosolids and introduces dewatered cake blended in low proportion to the recirculating dry solids.

-

Compact FootprintSimplicity of the process allows that it can be retrofitted into existing spaces and for greenfield installations requires low space relative to the capacity achieved.

-

Low Air Emissions and OdorsResulting from operation under strong vacuum without introduction of external air. This allows the technology to operate well with a wide range of sludge types and incoming moisture levels

Applications

The future of waste is here

Join Heartland in transforming waste through sustainable solutions. Reach out today.