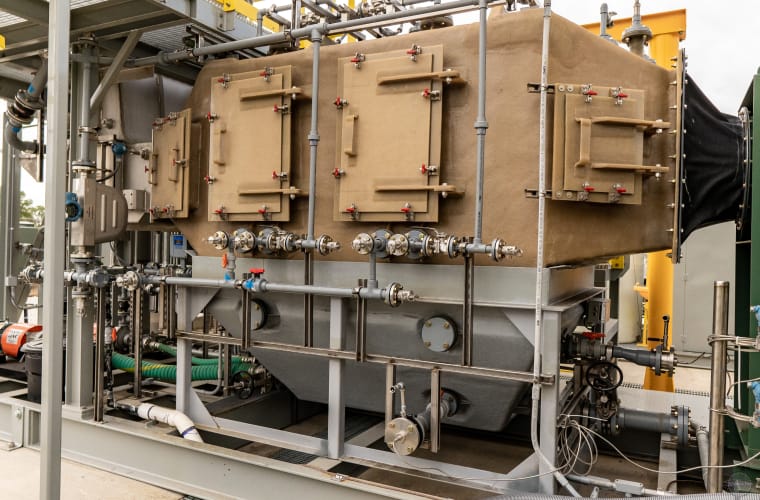

Heartland Concentrator™

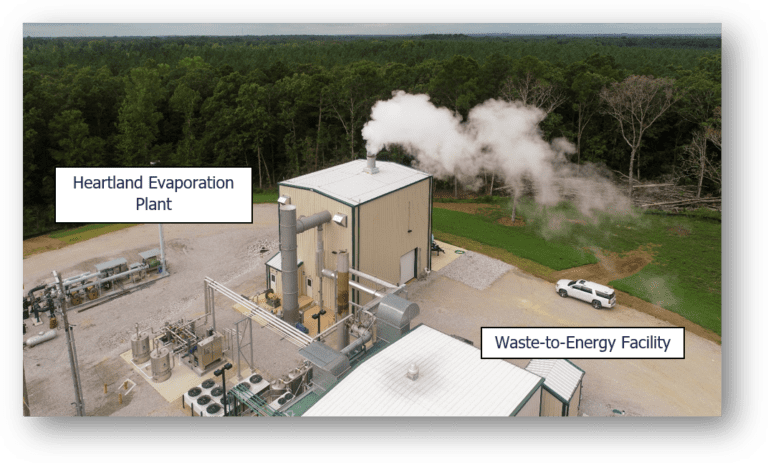

Heartland’s concentrator technology enables on-site wastewater evaporation, lowering environmental impact.

Low-temperature, high-turbulence evaporation

The Heartland Concentrator™ is a direct-contact evaporator where hot gasses are mixed with wastewater in a proprietary process. By utilizing direct contact with hot gas and wastewater inside a compact evaporation zone, the Concentrator avoids relying on heat exchangers that are prone to fouling.

Award winning and industry recognized

In 2022, WM’s 120K GPD leachate evaporation project, developed in partnership with Heartland, was shortlisted for the Global Water Intelligence’s 2022 Industrial Project of the Year. In 2021, ACEC selected Heartland’s Evaporation Facility at the Three Rivers Regional Landfill as the most unique, innovative, and socially impactful engineering project.

How it works

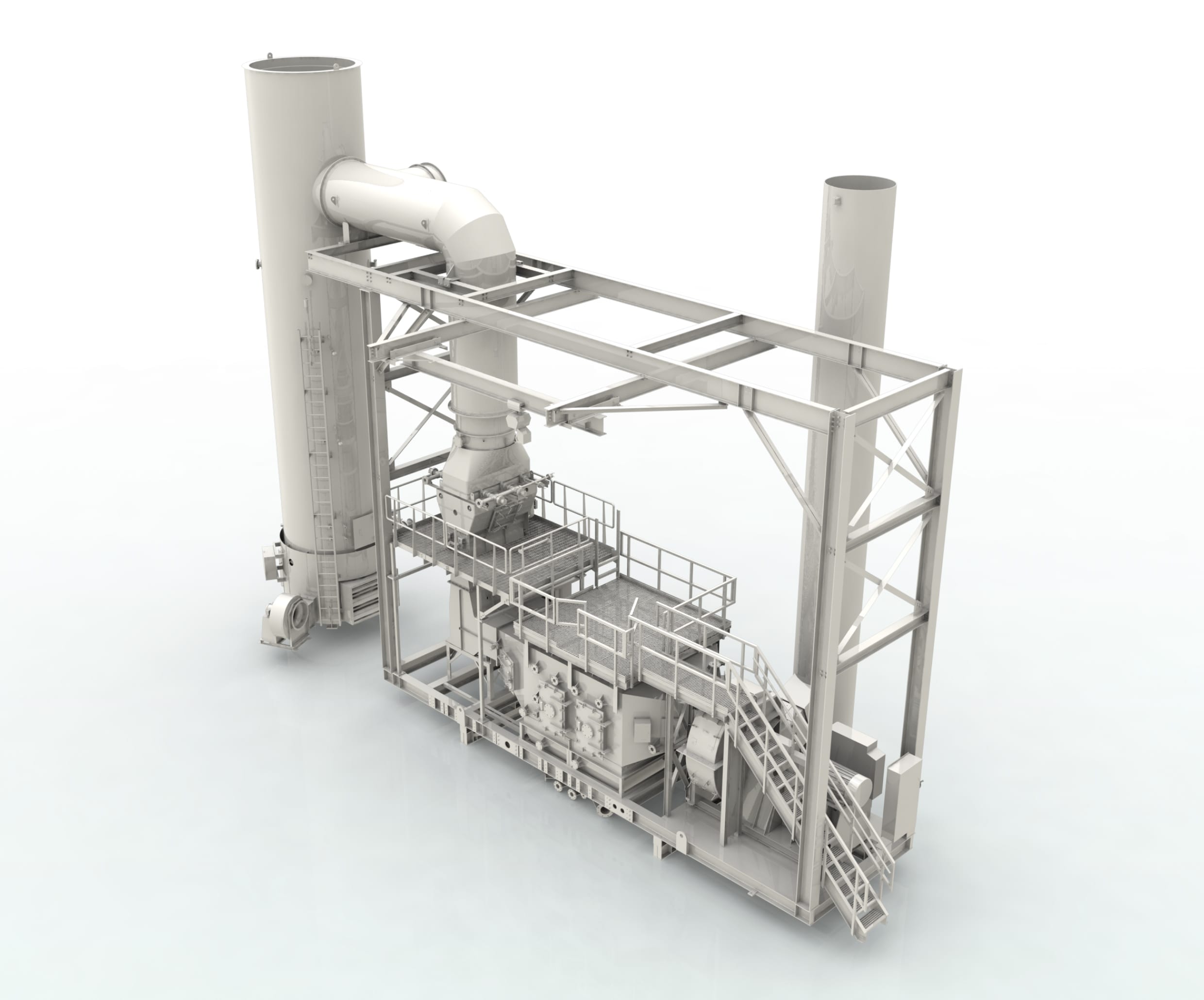

1. Thermal Energy Supply

The Concentrator is uniquely flexible and able to utilize a variety of waste heat sources including turbines, engine, and biogas. Thermal energy is supplied from a variety of possible sources.

1. Thermal Energy Supply

The Concentrator is uniquely flexible and able to utilize a variety of waste heat sources including turbines, engine, and biogas. Thermal energy is supplied from a variety of possible sources.

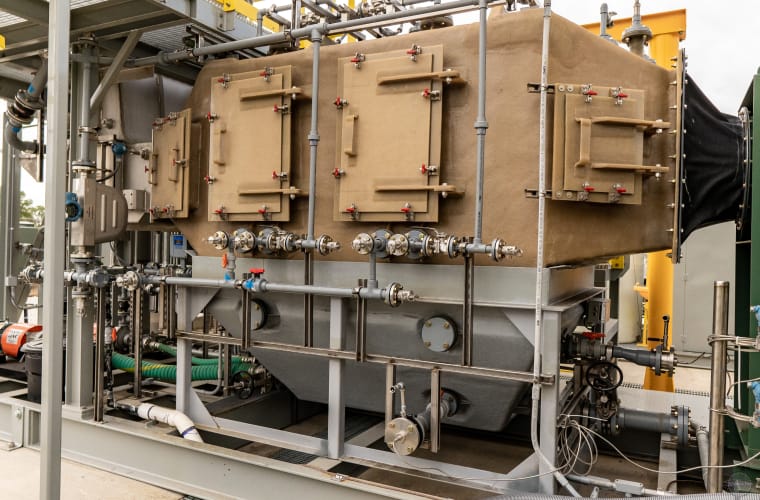

2. Wastewater Feed & Evaporation Zone

Heartland’s evaporation zone creates acres per minute of dynamic surface area between liquid and gas phases to stimulateing rapid evaporation. To reduce fouling, intentionally large liquid droplets are injected into the highly- turbulent hot gas flow.

2. Wastewater Feed & Evaporation Zone

Heartland’s evaporation zone creates acres per minute of dynamic surface area between liquid and gas phases to stimulateing rapid evaporation. To reduce fouling, intentionally large liquid droplets are injected into the highly- turbulent hot gas flow.

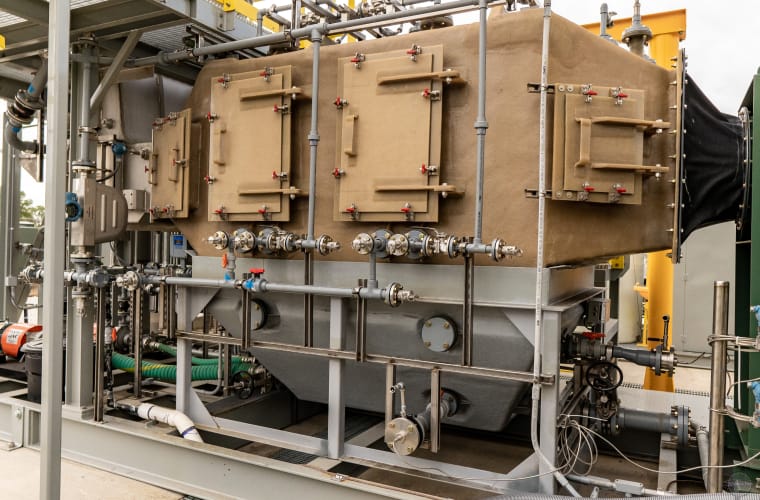

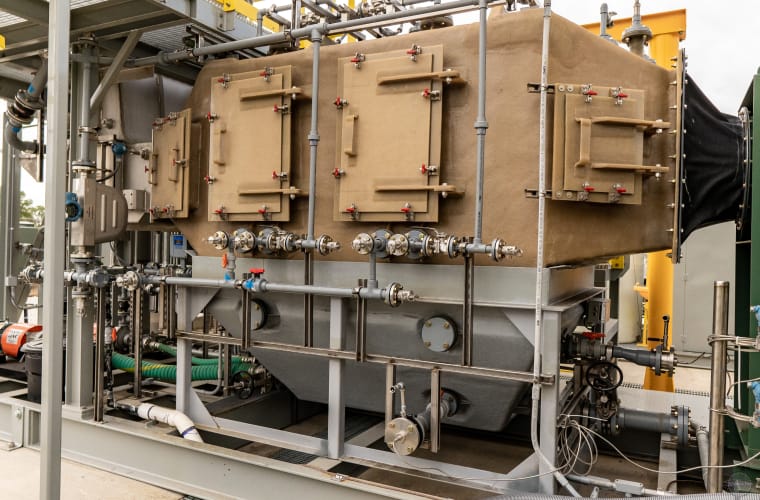

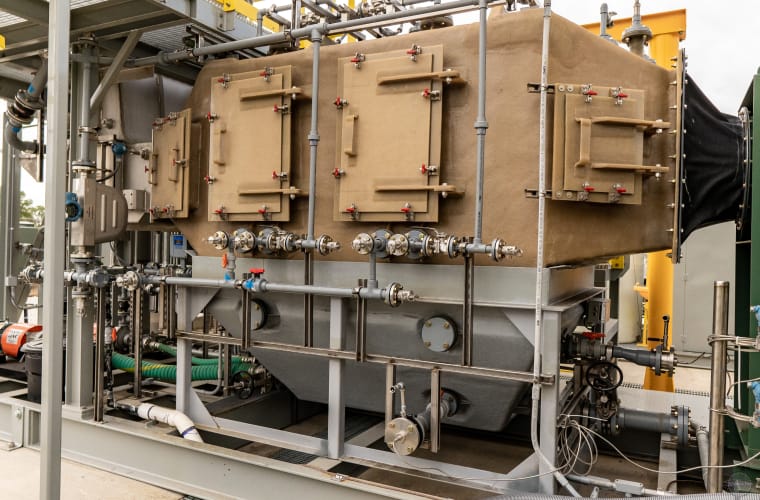

3. Mist Eliminator System

Cooled water vapor passes through a high-efficiency, 3-stage mist elimination process. Entrained droplets and particulate matter coalesce on a large surface area are separated from the vapor flow and collected in the sump below.

3. Mist Eliminator System

Cooled water vapor passes through a high-efficiency, 3-stage mist elimination process. Entrained droplets and particulate matter coalesce on a large surface area are separated from the vapor flow and collected in the sump below.

4. Draft Fan & Process Exhaust Stack

The process operates under a vacuum with a draft fan pulling water vapor over and through the mist eliminators. The cooled, clean water vapor and thermal combustion gases are discharged through the exhaust stack.

4. Draft Fan & Process Exhaust Stack

The process operates under a vacuum with a draft fan pulling water vapor over and through the mist eliminators. The cooled, clean water vapor and thermal combustion gases are discharged through the exhaust stack.

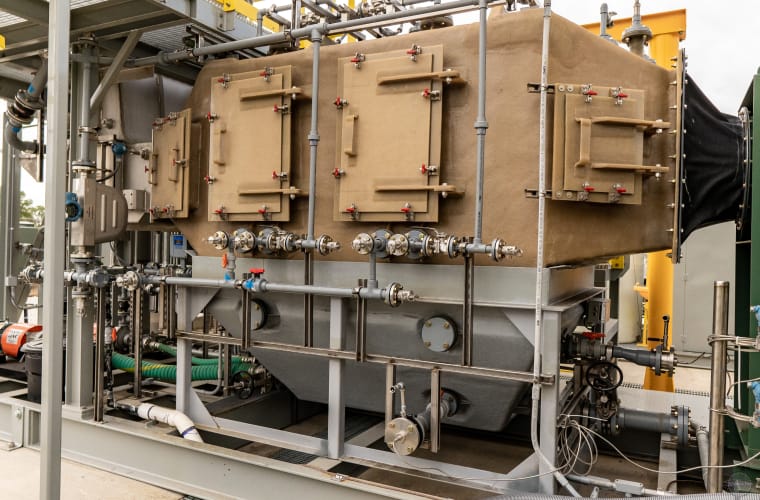

5. Recirculation, Residual & Disposal

Residual feed collected in the sump below is recirculated to drive further cycles of concentration, allowing precise process control. Recirculation allows the system to achieve an up to 25x concentration factor or 90% volume reduction in some applications. The sump is purged periodically for residual and brine disposal or ZLD solutions including dewatering.

5. Recirculation, Residual & Disposal

Residual feed collected in the sump below is recirculated to drive further cycles of concentration, allowing precise process control. Recirculation allows the system to achieve an up to 25x concentration factor or 90% volume reduction in some applications. The sump is purged periodically for residual and brine disposal or ZLD solutions including dewatering.

-

Low TemperatureOur proprietary approach is manufactured and designed with corrosion-resistant materials, avoiding fouling and corrosion and enabling uptime.

-

Direct ContactThe Heartland system replaces the need for heat exchangers used by traditional evaporators by directly contacting hot gas with wastewater feed within a compact turbulent evaporation zone.

-

Leverage Waste HeatThe system is flexible to thermal sources, including gas (natural gas, landfill gas, or biogas) flares, turbine, engine & stack exhaust, or a combination of these as the primary thermal energy source.

LM-HT® Process

The Heartland Concentrator™ process utilizes patented low-temperature, direct-contact evaporation technology to efficiently treat challenging waste streams, uniquely transforming wastewater into clean water vapor and minimizing residual waste in an energy-efficient and sustainable manner.

Configurations

The Heartland Concentrator™ has several configurations, suitable for specific applications.

-

ROVap™ROVap™ is on-site Reverse Osmosis concentrate eVAPoration. Award-winning and industry recognized, Heartland’s ROVap™ configuration is an energy efficient and environmentally sustainable solution for treating difficult to manage Reverse Osmosis waste concentrate.

-

CoVAP™CoVAP™ stands for ‘COgeneration for industrial eVAPoration’. Heartland is the leading solution provider with technology that can directly utilize waste heat from non-traditional sources such as engine and turbine exhaust to evaporate challenging water.

-

HybridHeartland’s Hybrid configuration brings ultimate value to a customer with available exhaust heat from an on-site landfill gas powered engine. The configuration ducts together thermal energy from engine exhaust with heat from a biogas or landfill gas flare, reducing ongoing energy costs while providing flexibility to increase evaporation capacity when required.

A proven technology for wastewater

-

%volume reduction

-

Award Winningfrom industry recognized organizations

-

+years of operation

Applications

The future of waste is here

Join Heartland in transforming waste through sustainable solutions. Reach out today.