HelioStorm™

The Heartland HelioStorm™ is an ultra-high temperature ionic plasma synthesis reformer that’s both environmentally friendly and cost effective.

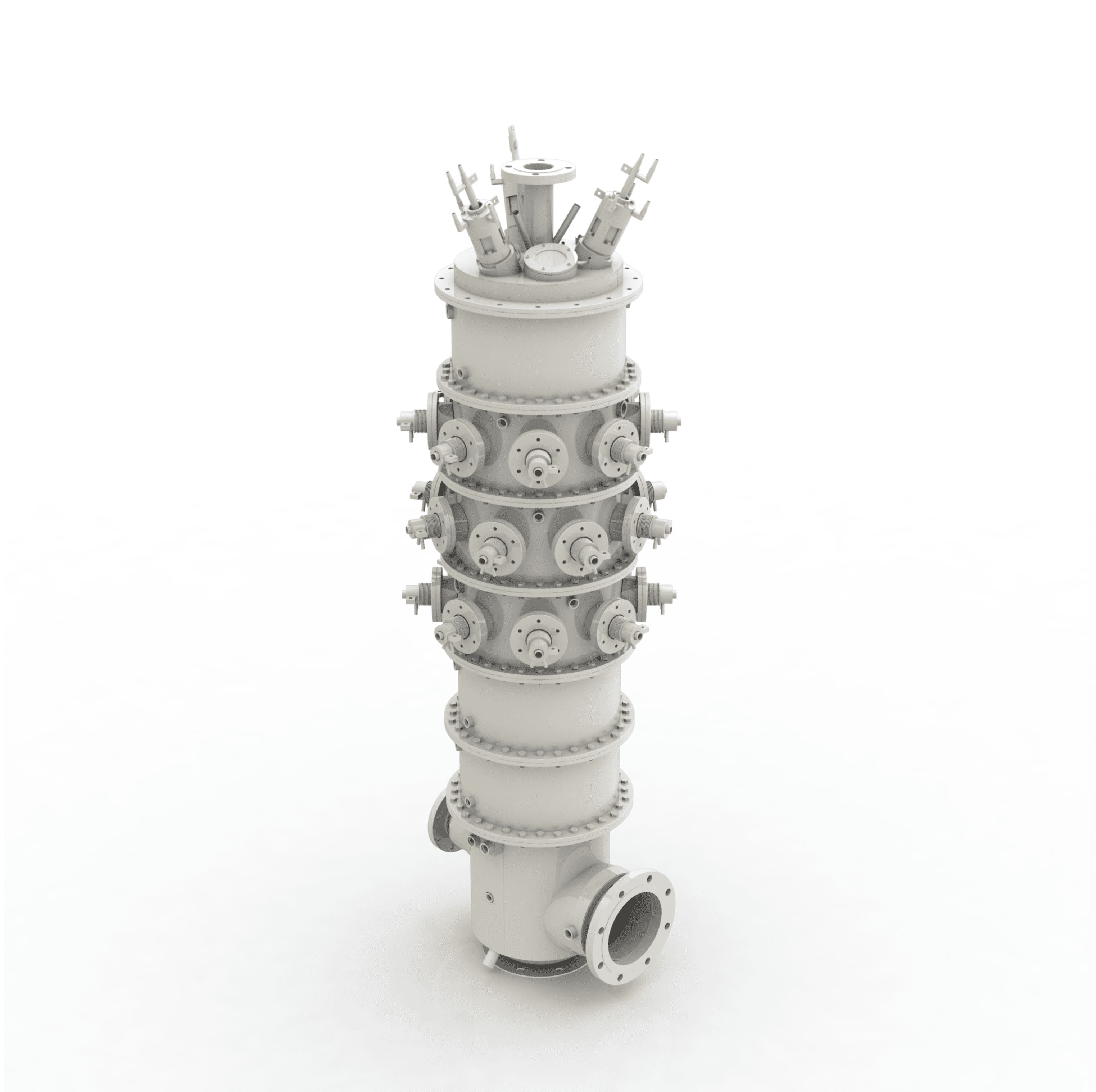

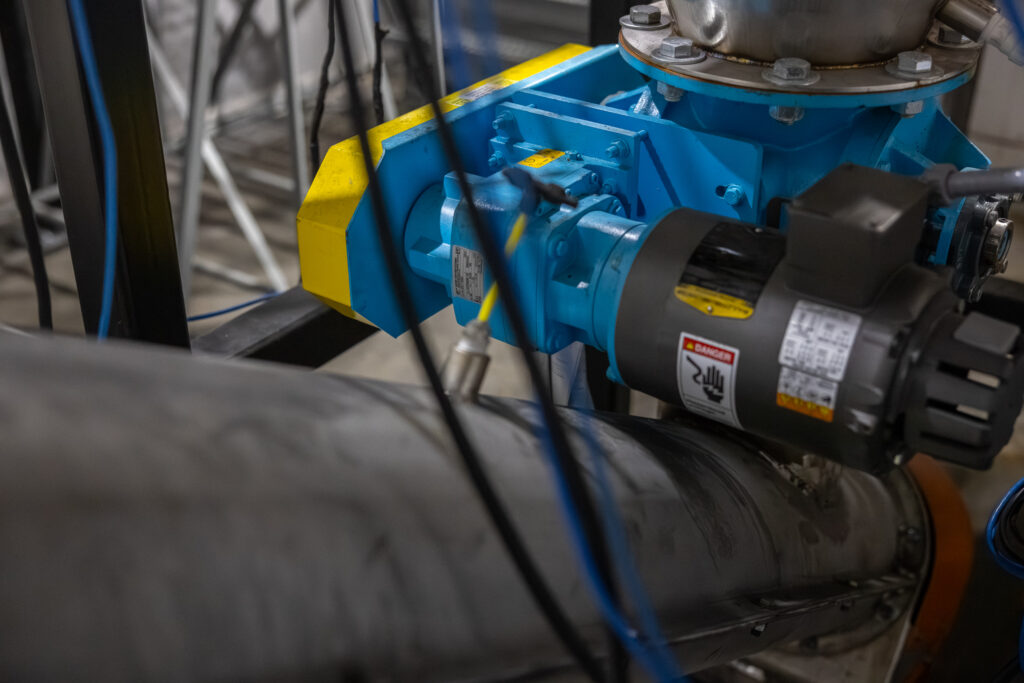

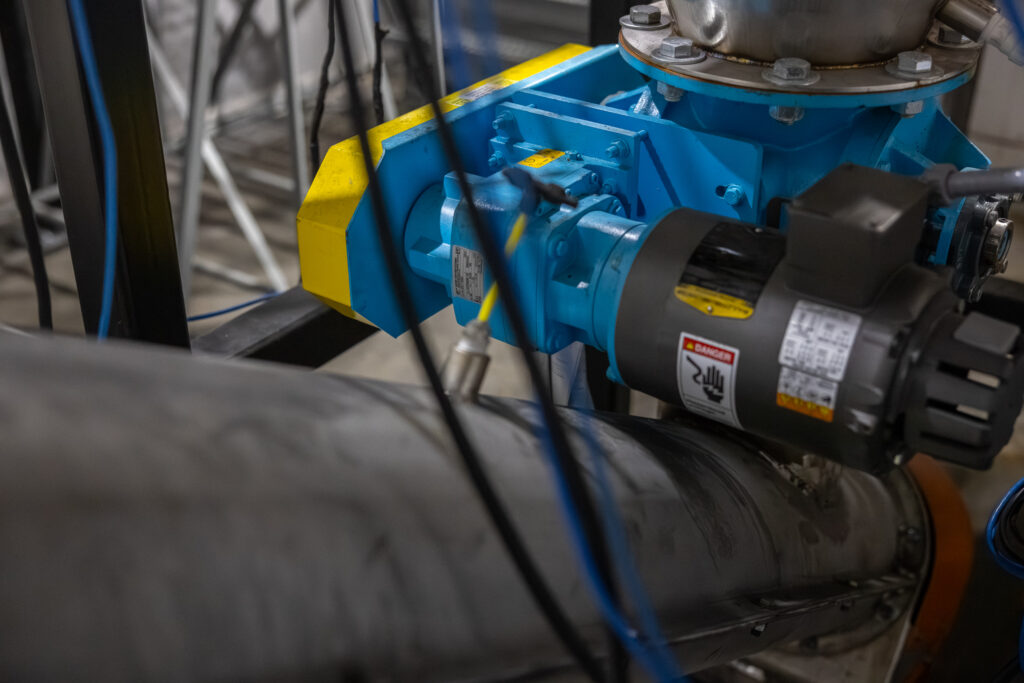

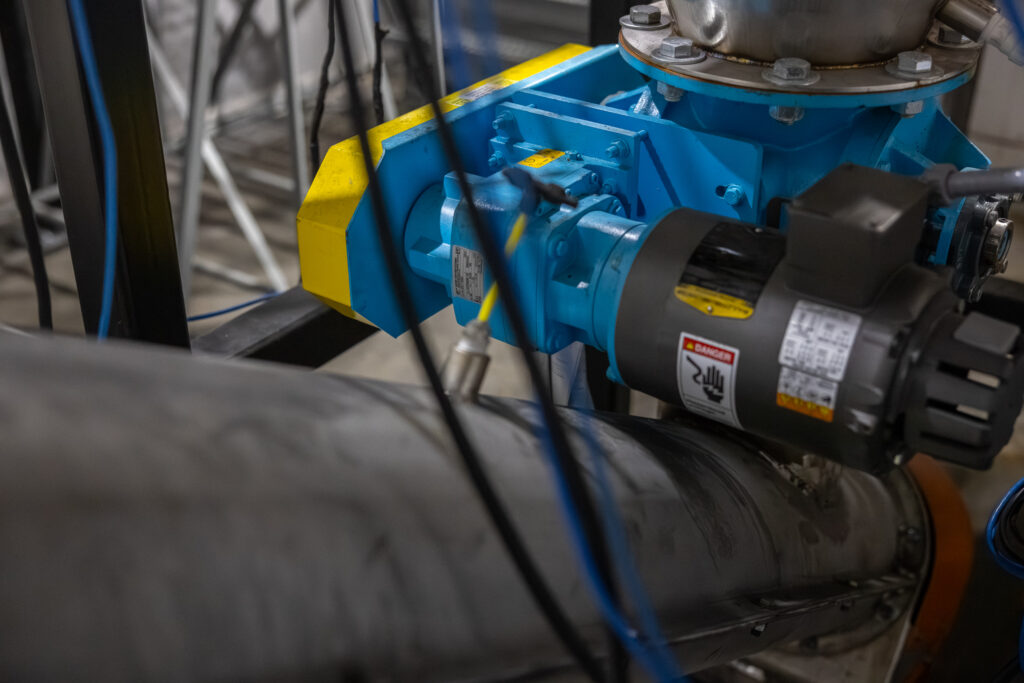

Plasma synthesis reformer (PSR)

HelioStorm™ is an ultra-high temperature, ionic, plasma synthesis, reforming technology that converts dry organic feedstocks in an environmentally friendly way. Utilizing HelioStorm's ultra-high temperature process, solid waste feedstocks convert into clean energy products at compact, distributed scale.

How it works

1. Thermal Energy Supply

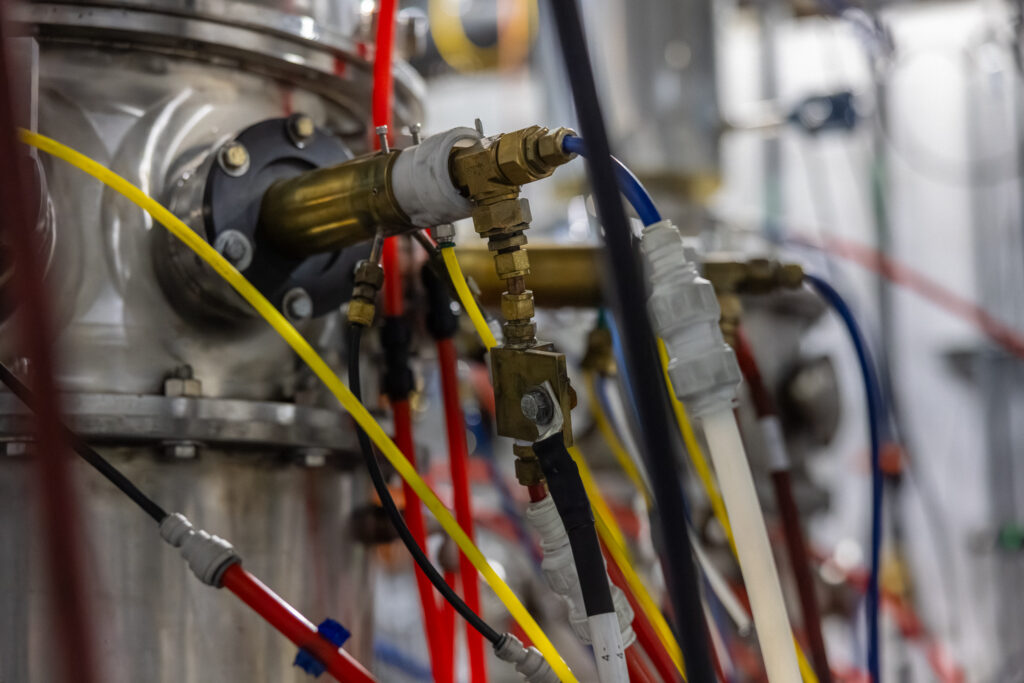

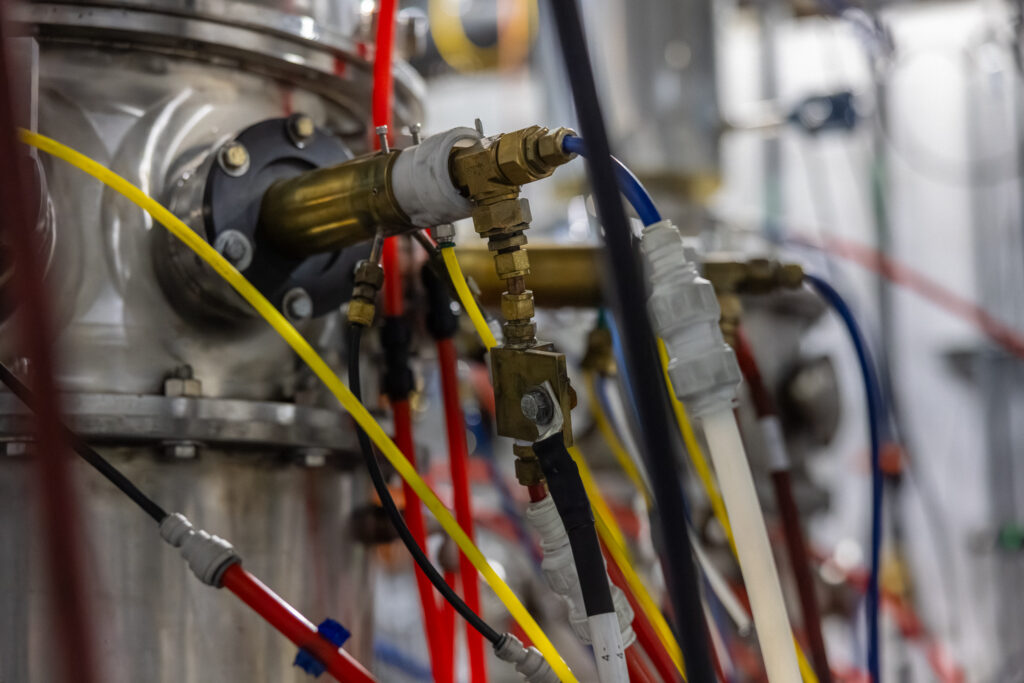

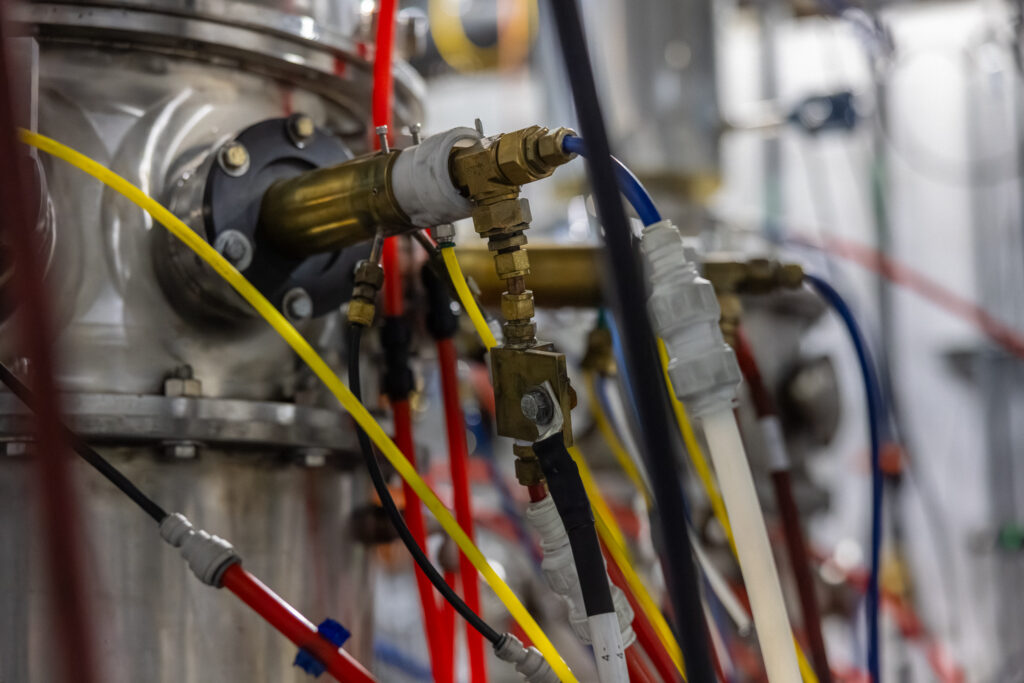

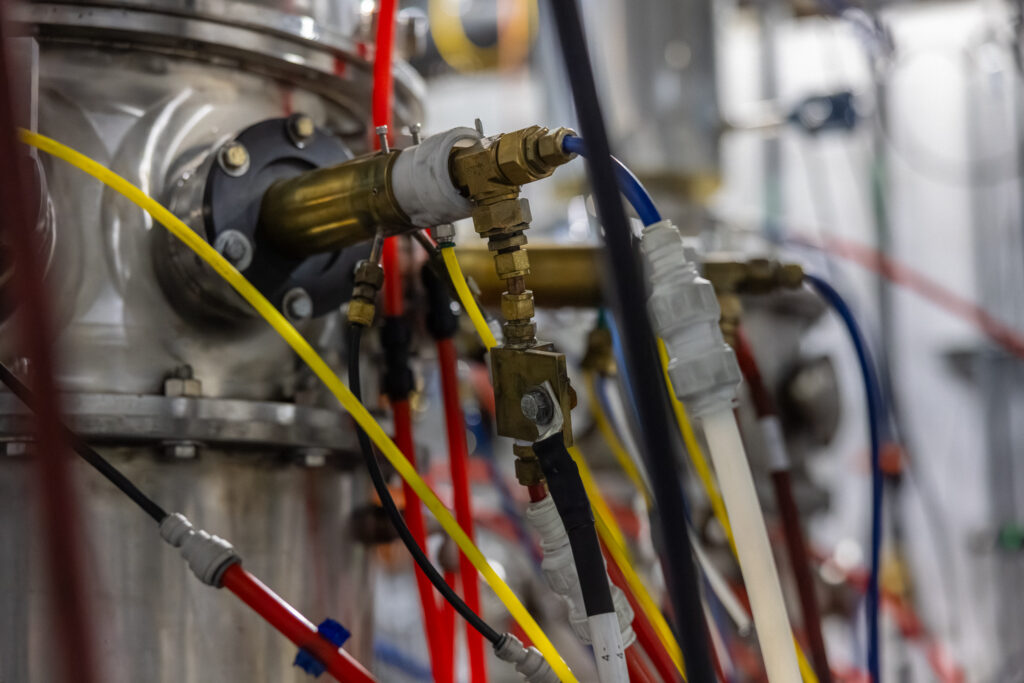

Carrier gas (N2) enters the reactor and electrode pairs are energized to create multiple uniform high-temperature plasma fields.

1. Thermal Energy Supply

Carrier gas (N2) enters the reactor and electrode pairs are energized to create multiple uniform high-temperature plasma fields.

2. Feeding Zone

Dried organic feedstocks enter the top of the reactor for preconditioning via top torch.

2. Feeding Zone

Dried organic feedstocks enter the top of the reactor for preconditioning via top torch.

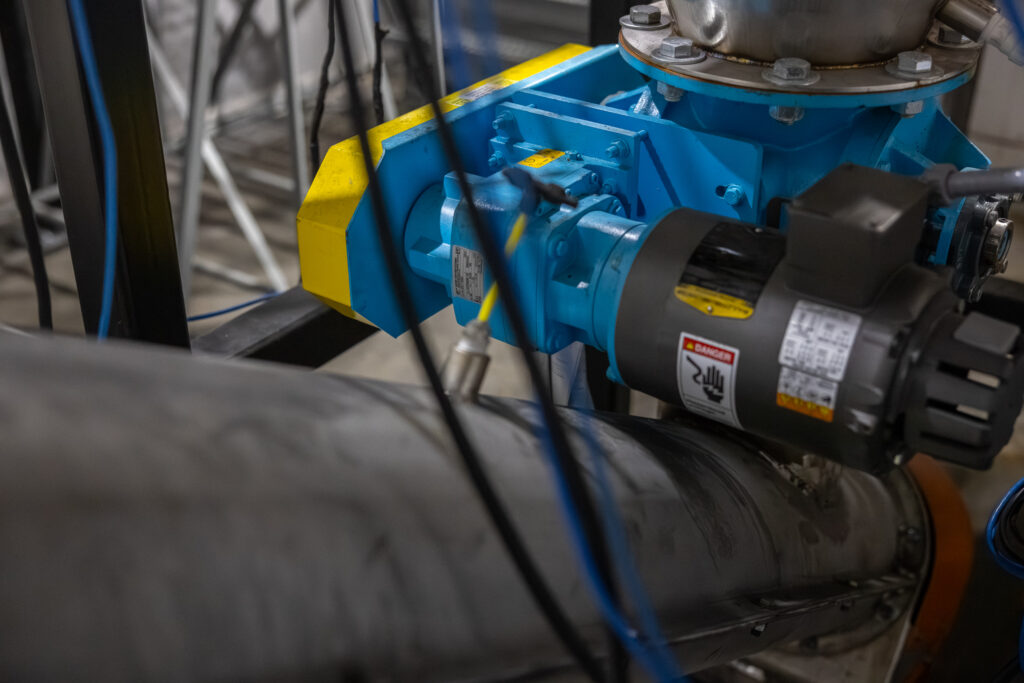

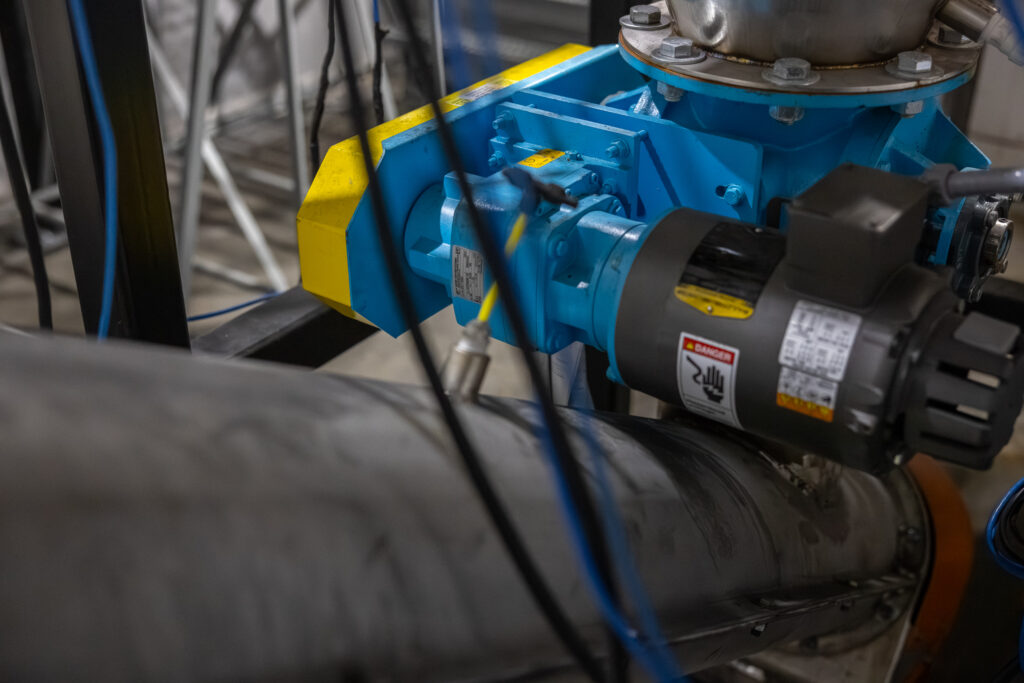

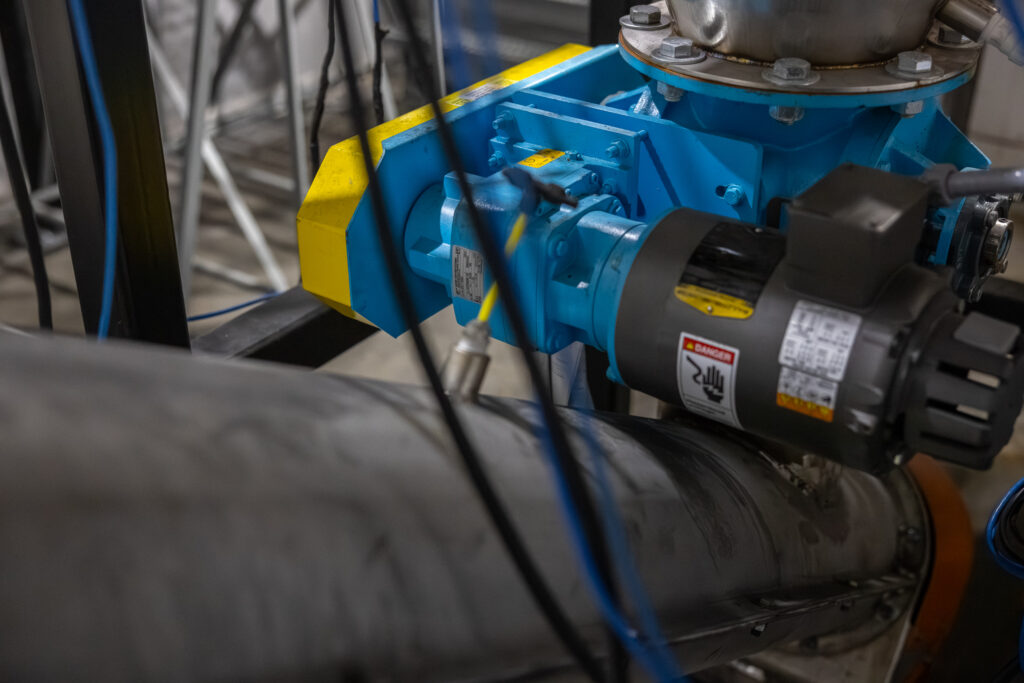

3. Ionic Reforming

Ionic reforming proceeds at ultra-high temperature (avg. 5,000°C) in a low-oxygen environment. Atoms and ions dissociate into atomic species.

3. Ionic Reforming

Ionic reforming proceeds at ultra-high temperature (avg. 5,000°C) in a low-oxygen environment. Atoms and ions dissociate into atomic species.

4. Synthesis Zone

Quenching occurs and particles rapidly cool into their lowest energy state: H2 and CO gas.

4. Synthesis Zone

Quenching occurs and particles rapidly cool into their lowest energy state: H2 and CO gas.

5. Clean Syngas

A clean “tar-free” syngas (H2 & CO) is produced, free of long chain carbon-containing compounds requiring further polishing. Syngas can be converted to fuels (methanol, diesel), separated to capture hydrogen and carbon monoxide gas, or used to feed the genset to make electricity.

5. Clean Syngas

A clean “tar-free” syngas (H2 & CO) is produced, free of long chain carbon-containing compounds requiring further polishing. Syngas can be converted to fuels (methanol, diesel), separated to capture hydrogen and carbon monoxide gas, or used to feed the genset to make electricity.

6. Char

PFAS-free char is eligible for a wide range of disposal outlets.

6. Char

PFAS-free char is eligible for a wide range of disposal outlets.

-

Ultra-High TemperatureHelioStorm achieves temperatures between 3,000 and 10,000°C, maintaining an average temperature of 5,000°C across the reactor’s entire plasma field.

-

Assured PFAS DestructionDestroys PFAS compounds at reaction rates well above other thermal technologies.

-

Plasma SynthesisThe treatment and proceeding quench of feedstock compounds creates clean syngas, ideal for creating new molecules like low carbon fuels and chemicals.

Plasma Synthesis Reforming

HelioStorm is an ultra-high temperature ionic plasma synthesis reformer, capable of converting the widest range of feedstocks into beneficial energy sources while eliminating contaminants.

A differentiated reformer

Electrically driven and combustion-free, Heartland’s ultra-high temperature process destroys chemical contaminants and PFAS without the need for a thermal oxidation step.

-

Tar freeprocess

-

thstate of matter

-

3000-10000°Coperating temperature

Applications

The future of waste is here

Join Heartland in transforming waste through sustainable solutions. Reach out today.