CHALLENGE

To transition toward future ELG compliance, the power industry has evaluated many technologies in recent years. Many of these technologies were found to be cost prohibitive, resource intensive, or excessively challenging to operate due to:

Scaling of heat exchanger surfaces and other process equipment resulting in excessive downtime and cleaning.

Chemical pretreatment requirements resulting in additional process complexity, waste disposal, and prohibitive operating costs

Operational hypersensitivity to changes in water chemistry requiring significant monitoring technology and laboratory resources to mitigate process upsets and resulting downtime.

SOLUTION

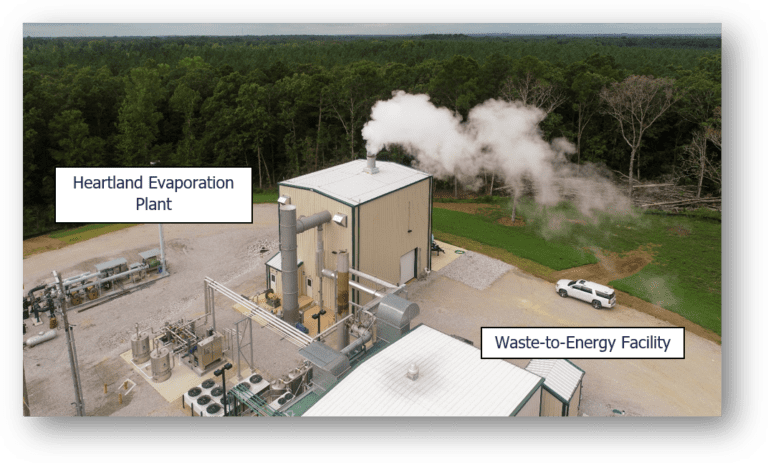

Heartland developed an integrated design utilizing flue gas from a utility’s air quality control system as the sole thermal energy source for evaporation. This configuration is attractive for many reasons:

Flue gas is a viable waste-heat energy source, providing favorable economics for evaporative wastewater treatment compared to other energy sources.

Integration as a closed-loop vapor system would allow for concentrator operation without effect on current air emissions or permitting.

Entrained fly ash in the flue gas provides suspended particulates that may aid in solidification and stabilization of residuals as part of a (ZLD) process.